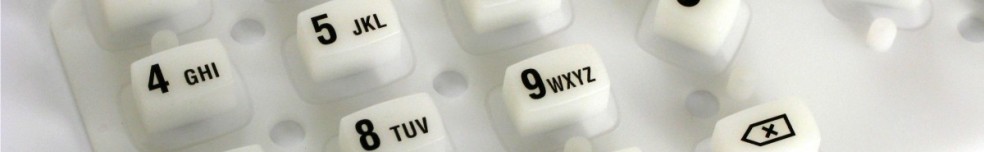

Rubber keypads

They are an interesting alternative for membrane keyboards. Their production technology has opened up great opportunities for devices designers in terms of shape and surface finish. Properties of silicone are successfully used for various technologies of interface illumination.

Below we present a standard constructions using silicone keypads. We would like to point out that every project is always an individual matter so the design of the product may be different.

Membrane keyboard with rubber overlay

Rubber overlay is the top layer of a membrane keyboard. This gives the possibility, firstly, to design the keys with a greater height and unusual shape, and secondly, to use edge backlight in an LGF technology (Light Guide Film).

Rubber keypad on the printed circuit with switches

Switches are located on the printed circuit board.. Shape and height of the keys and the overlay itself are more optional than in case of tradictional membrane keyboard with an overlay. With this feature, we obtain a three-dimensional shape of the keyboard, which can be synchronized with the machine design.

Rubber keypad with carbon contacts on the printed circuit board

In case of a need for bigger key travel (0,8-1,5mm) than in standard switches, a keypad with a specially designed membrane (which acts as a swich) is used. Depending on customer requirements keyboards with different contact force can be designed. The contact element in the form of a conductive disc is inserted at the bottom of the key.

Rubber keypad with namaplate

Additional film layer is used when the use of more descriptions or sophisticated graphic design is required. The advantage of this solution is the ability to perform multiple graphical and descriptive variants while maintaining common rubber overlay. This means lower tooling costs for many devices with the same casing but divided into different types depending on their functionalities.