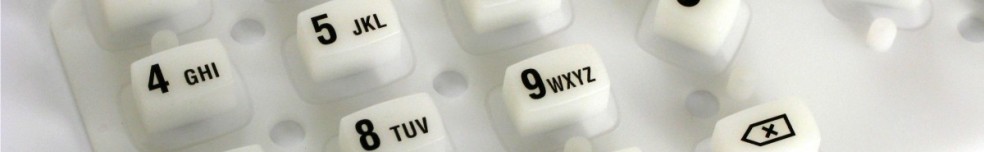

Rubber keypads | Types of keys

Rubber keypads are produced in the process of silicone vulcanization. Then they are subjected to different technological processes based on customer needs and purposes of use.

Tampography

Printing is made on the surface of a keypad. After printing, the surface is coated with a special layer of polyurethane which increases wear resistance.

Printing can be multicoloured.

Silicone is dyed in the mass to the desired colour In case of backlight, transparent silicone is used.

Spray painting + laser engraving

A dedicated solution for backlit applications.

Colourless rubber keypad is sprayed with several layers of paint to the desired colour. Then, the top layer of paint is engraved in the shape of illuminated elements exposing the colour beneath it.

Epoxy-coated keys

The key surface is covered with a layer of epoxy resin which gives it a crystal shine.

The keypad gets interesting aesthetic effect. The solution can be combined with the technology of spray painting or tampography.

The keys are almost completely resistant to abrasion.

PMMA overlay on the keys

The most complex technology that connects two different manufacturing processes– silicone vulcanization and PMMA injection mould.

The keys are glued to silicone with special adhesive. Printing is made from the bottom of the keys(tampography) or with a spray painting technique from the top + engraving.

Depending on the needs, the keys can be illuminated or not.